Should cost modeling software is a valuable tool for businesses seeking to accurately predict the future costs of their products or services. This type of software can help companies make informed decisions related to pricing, production, and other factors that impact costs.

With the ability to investigate different scenarios and determine the most cost-effective way forward, should cost modeling software can help companies boost their competitive edge and make confident decisions. Whether you’re in manufacturing, supply chain management, or any other industry, investing in high-quality should cost modeling software can help you stay ahead of the curve and drive success for your business.

Understanding Should Cost Modeling

Should cost modeling software is a tool that allows supply chain teams to determine the actual cost of goods and services purchased. Using this software, businesses can make informed decisions about pricing, production, and other factors that affect costs, ultimately helping them become more competitive in their market.

GEP NEXXE and MTI Systems are some popular should cost modeling software providers.

Understanding Should Cost Modeling Should Cost Modeling is a cost estimation technique used by businesses to understand the actual cost of products or services. This methodology is based on a thorough analysis of all the elements that contribute to the final cost of delivering a particular product or service. It involves breaking down the components of a product or service and analyzing their individual costs. This way, businesses can understand the actual costs involved in each stage of production. H3: Definition Should Cost Modeling is a technique used to estimate the actual cost of delivering a product or service by analyzing the individual components’ costs. The process helps businesses to understand the elements that contribute to a product’s cost and optimize their production and sourcing strategies accordingly. H3: Benefits of Should Cost Modeling Here are some benefits of Should Cost Modeling: – Accurate cost estimation: Should Cost Modeling provides businesses with an accurate estimate of the actual costs involved in product or service delivery. This information helps companies to make better-informed decisions about pricing, sourcing, and production. – Process optimization: By understanding the cost structure of a product or service, businesses can optimize their processes and identify areas where they can reduce costs. – Improved supplier relationships: With Should Cost Modeling, businesses can negotiate better with suppliers by being able to compare actual costs with supplier quotes. This information helps build stronger supplier relationships and can lead to cost savings. – Enhanced decision-making: Should Cost Modeling provides businesses with the information they need to make more informed decisions about sourcing, pricing, and production. – Cost savings: By identifying areas where they can optimize their processes and reduce costs, businesses can achieve significant cost savings. H3: Purpose of Cost Modelling The purpose of cost modeling is to provide businesses with an accurate estimate of the actual costs involved in delivering a product or service. This information helps companies to make better-informed decisions about pricing, sourcing, and production. Cost modeling is a critical tool for optimizing processes, identifying cost-saving opportunities, and building stronger supplier relationships. Ultimately, this leads to more informed decision-making, cost savings, and improved overall business performance. In conclusion, Should Cost Modeling is a critical tool for businesses looking to gain a competitive edge. By analyzing individual components’ costs, businesses can optimize their processes, identify cost-saving opportunities, and build stronger supplier relationships. This methodology provides businesses with the information they need to make more informed decisions about pricing, sourcing, and production, ultimately leading to improved overall business performance.

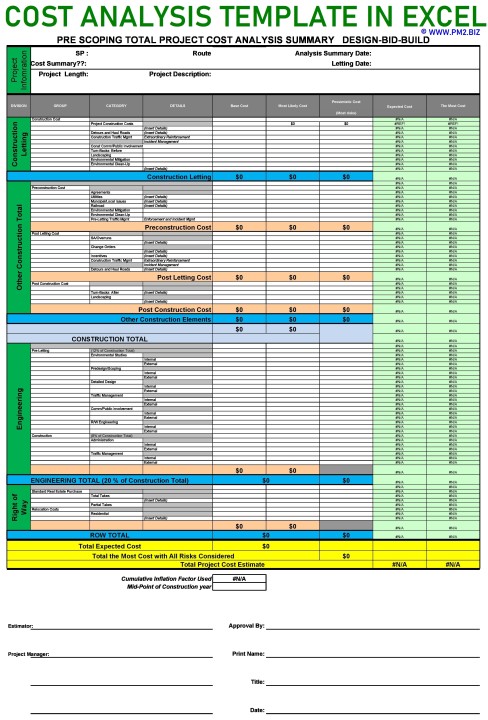

Credit: www.projectmanager.com

Exploring Should Cost Modeling Software

Gain insight into the true costs of goods and services with Should Cost Modeling software. Used to create predictive models that help businesses make informed decisions, Should Cost Modeling can improve supplier relationships, build trust and aid in negotiations. Explore centralized tools from companies like GEP NEXXE and MTI Systems to streamline cost estimation for better informed decision making.

Overview

Exploring should cost modeling software is essential for organizations looking to optimize their cost estimation processes, especially in supply chain management and manufacturing. The software enables businesses to determine the true cost of goods and services, negotiate with suppliers, and make informed decisions about pricing and production.Top Should Cost Modeling Software

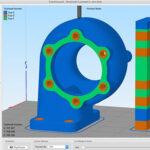

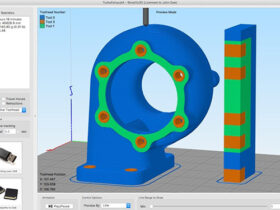

Two top should cost modeling software in the market are GEP NEXXETM and MTI Systems’ Should Costing. GEP NEXXETM features a centralized should-cost modeling tool that enables supply chain teams to determine the true price of goods and services purchased at an enterprise level. MTI Systems’ Should Costing software purpose is to arrive at a cost estimate which can guide negotiations.Features Of Gep Nexxetm

GEP NEXXETM software is equipped with useful features that make price control more manageable. It has a should-cost model that enables users to estimate a product’s cost based on the raw materials, labor, and overhead costs. Other features include real-time cost analysis, supplier performance tracking, and automated supplier scorecard creation.Advantages Of Mti Systems’ Should Costing

One advantage of MTI Systems’ Should Costing software is its ability to compare and analyze costs across the entire supply chain. The tool provides detailed cost information for each phase of the product development process, thus enabling users to identify areas for cost reduction. Additionally, should costing promotes transparency between buyers and suppliers, enhancing collaboration and trust. In conclusion, should cost modeling software is crucial in cost estimation and supply chain management. By using the right software, businesses can save substantial costs and improve their bottom line.How Should Cost Modeling Software Revolutionizes Cost Estimation

Should Cost Modeling Software has revolutionized cost estimation by providing the ability to determine the true price of goods and services purchased. With centralized tools for accurate predictions, businesses can make informed decisions about pricing, production, and other factors that affect costs, improving their competitive edge.

How Should Cost Modeling Software Revolutionizes Cost Estimation Cost estimation is a crucial aspect of any manufacturing business. Without accurate cost estimates, it becomes challenging to make data-driven decisions and stay ahead of the competition. However, manual cost estimation is often time-consuming and prone to errors, which can lead to higher expenses and lost opportunities. This is where Should Cost Modeling Software comes into play. This powerful tool makes cost estimation faster, more accurate, and more efficient than ever before. In this post, we’ll focus on how Should Cost Modeling Software revolutionizes cost estimation. We’ll explore three key features of this software that make it a game-changer for manufacturers across industries. H3: Centralizing Should-Cost Modeling Should Cost Modeling Software centralizes all cost estimation data in one place, making it easier to access, manage, and analyze. Instead of relying on scattered spreadsheets and documents, manufacturers can store all their data in a centralized database accessible by multiple users. This ensures consistency and accuracy in cost estimation across all teams. Moreover, centralizing cost estimation data streamlines the entire process, allowing manufacturers to iterate faster and make better decisions. Teams can collaborate more effectively, share their insights, and reach data-driven decisions quickly. H3: Digital Manufacturing Simulations Another important feature of Should Cost Modeling Software is the ability to simulate digital manufacturing scenarios. This powerful tool generates simulations of manufacturing processes, enabling manufacturers to identify potential bottlenecks and cost drivers before they occur. With digital manufacturing simulations, manufacturers can optimize their manufacturing processes, reducing costs and improving efficiency. Manufacturers can adjust variables, such as process parameters, raw materials, and equipment configurations to identify the optimal conditions for producing quality products at lower costs. H3: Empowering Data-Driven Decisions Finally, Should Cost Modeling Software empowers data-driven decision-making. By centralizing cost estimation data and providing digital manufacturing simulations, manufacturers have access to comprehensive data that they can use to make informed decisions. With this software, manufacturers can access historical data and trends, identify patterns and outliers, and generate reports and dashboards. This enables manufacturers to make better decisions based on real-time data and insights instead of relying on guesswork, assumptions, or intuition. In conclusion, Should Cost Modeling Software revolutionizes cost estimation by centralizing cost estimation data, providing digital manufacturing simulations, and empowering data-driven decision-making. This software drives efficiency, generates more accurate cost estimates, and provides valuable insights that manufacturers need to thrive in today’s competitive landscape.

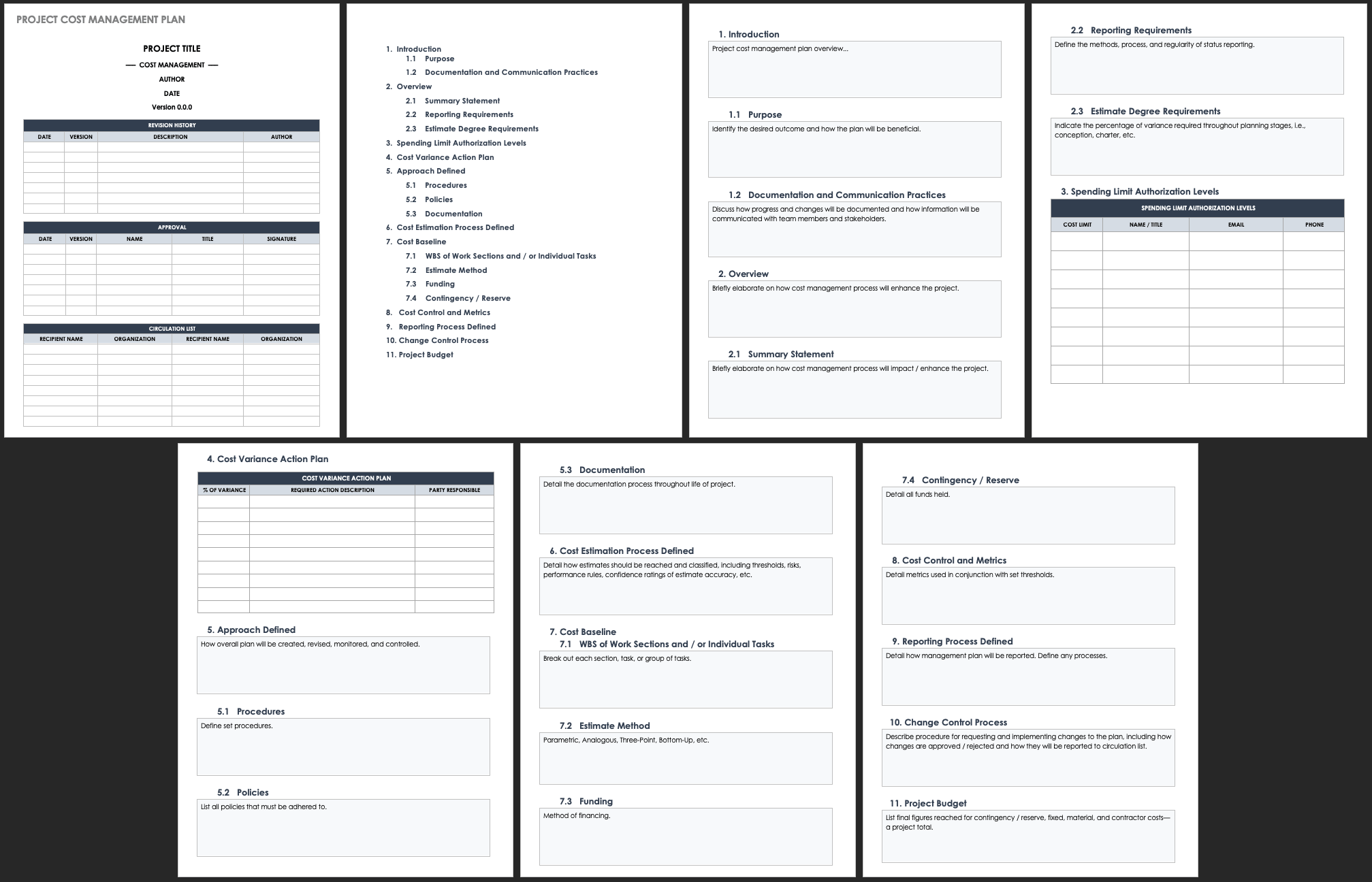

Credit: www.linkedin.com

Implementing Should Cost Modeling Software

Implementing Should Cost Modeling software can provide precise cost estimates and improve supply chain management. It assists the businesses in making informed decisions about pricing, production, and other cost-effective factors. GEP NEXXETM and MTI Systems are some of the tools providing centralized should-cost modeling.

Implementing Should Cost Modeling Software Implementing should cost modeling software can revolutionize the way companies approach cost estimation, procurement, and supply chain management. With the right software, companies can generate accurate estimates of the true cost of goods and services, enabling them to negotiate better contracts and make informed sourcing decisions. But how exactly can companies implement should cost modeling software, and what use cases are there for custom, engineer-to-order, and contract manufacturers? Use Cases for Custom, Engineer-to-Order, and Contract Manufacturers One of the main benefits of should cost modeling software is its versatility. It can be used across a wide range of manufacturing scenarios, including custom, engineer-to-order, and contract manufacturing. Here’s a closer look at each of these use cases:Custom Manufacturing

Custom manufacturing is the production of unique products that are designed and built to meet a specific customer’s needs. Because each product is unique, cost estimation can be a challenge. However, should cost modeling software can help by analyzing the materials, labor, and overhead required to produce the product. This can help custom manufacturers generate accurate quotes, and ultimately, win more business.Engineer-to-order Manufacturing

Engineer-to-order (ETO) manufacturing involves designing and building highly customized products to meet a customer’s unique needs. Because ETO products are highly complex and often require specialized tools and processes, accurate cost estimation is critical. Should cost modeling software can help ETO manufacturers by breaking down the costs of each component and process, enabling them to generate more accurate estimates and make informed sourcing decisions.Contract Manufacturing

Contract manufacturing is the outsourcing of a company’s manufacturing processes to a specialized third-party vendor. Because contract manufacturers provide a wide range of products, cost estimation can be challenging. However, should cost modeling software can help by analyzing the materials, labor, and overhead required to produce each product, enabling companies to negotiate better contracts and make informed sourcing decisions. Alignment of Product Development, Engineering, Manufacturing, and Sourcing Groups Implementing should cost modeling software also requires alignment between product development, engineering, manufacturing, and sourcing groups. By working together, these groups can ensure that the information required by the should cost modeling software is accurate and up-to-date. This can help companies generate more accurate cost estimates, make informed sourcing decisions, and ultimately, improve their bottom line.Best Practices For Successful Cost Estimation

Successful cost estimation is critical to any project. Should cost modeling software can help project managers to get precise should-cost estimates and determine the true price of goods and services purchased. GEP NEXXE and MTI Systems both offer centralized should-cost modeling tools that guide negotiations and compare to quotes provided by suppliers.

Though should cost modeling software has its advantages, stakeholders should be mindful of its limitations and should rely on cross-functional collaboration and expert opinions to develop successful cost estimates.

Best Practices for Successful Cost Estimation Defining Costing Goals and Objectives Before investing in a should cost modeling software, it is essential to define your costing goals and objectives. Determine what you want to achieve by using the software. Is it to reduce costs, improve supplier relationships, or enhance your decision-making process? Clearly defined goals will help you choose the right software and use it effectively. Selecting the Right Costing Solution Selecting the right costing solution is crucial to successful cost estimation. Consider factors such as pricing, the software’s functionality, and ease of use. Choose a software that fits your organization’s needs and budget. It is also essential to ensure that the software integrates with your existing tools and systems to avoid data duplication and increase efficiency. Training Team Members for Effective Use of Software To get the most out of your software, it is essential to train your team members effectively. Ensure that they understand the software’s functionality and are familiar with its features. Train them on how to interpret cost data and generate reports. This will empower your team to make informed decisions, ultimately increasing efficiency and saving costs. In conclusion, using should cost modeling software can help organizations make informed decisions about pricing, production, and other factors that affect costs. By following these best practices, organizations can ensure successful cost estimation and ultimately achieve their costing goals and objectives.Challenges And Solutions In Should Cost Modeling

Challenges in should cost modeling often arise due to the complex nature of supply chains, market fluctuations, and the availability of accurate data. However, advanced should cost modeling software offers solutions by providing centralized tools to determine the true cost of goods and services, guide negotiations, and compare quotes from suppliers.

This allows businesses to make informed decisions about pricing, production, and other factors affecting costs while building trust among buyers and suppliers.

Challenges and Solutions in Should Cost Modeling Should cost modeling is an essential part of any organization that deals with supplying goods or services. It helps companies predict a product’s costs and analyze its value to determine the most cost-effective way ahead. However, should cost modeling comes with numerous challenges that businesses must face and resolve to optimize the process. Here are three major challenges and their solutions:Data Accuracy And Validity

One of the significant challenges of should cost modeling is ensuring the accuracy and validity of data used in the process. Inaccurate data can lead to erroneous assumptions and, ultimately, poor cost estimates. To overcome this challenge, companies must obtain reliable and standardized data and review it frequently to ensure its validity. Also, they should invest in technologies that capture, validate, and analyze supplier data to ensure accuracy.Effective Supplier Relationship Management

Supplier relationship management (SRM) is crucial for cost modeling. Many suppliers offer a diverse range of products, services, and prices, making it challenging to determine which ones are cost-effective. Effective SRM can help to overcome this challenge by fostering long-term relationships with suppliers to facilitate data sharing and ensure mutual understanding. When suppliers are engaged and knowledgeable, they can provide valuable insights on production techniques and materials. Therefore, investing in supplier relationship management tools and software can be instrumental in improving the process.Continuous Cost Modeling Improvement

The process of cost modeling is inherently complex and requires continuous improvement to identify errors and refine the models. Therefore, companies must consistently review and optimize their cost models to ensure accuracy and reliability. This can be achieved by using software tools that offer advanced analytics and insights to monitor the success of cost models. Additionally, the process should be audited regularly by independent parties to ensure that the data and models remain relevant and up-to-date. In conclusion, should cost modeling is a crucial tool for businesses to make informed decisions about pricing, production, and other factors that affect costs. However, companies must address the challenges of data accuracy and validity, supplier relationship management, and continuous improvement in cost modeling processes to achieve optimal results. Investing in technology solutions and adopting best practices can help to achieve success in should cost modeling.

Credit: www.smartsheet.com

Frequently Asked Questions Of Should Cost Modeling Software

What Is The Should Cost Model?

The should-cost model is a process of predicting future costs of a product or service to make informed decisions on pricing and production. It enables businesses to investigate different scenarios and determine the most cost-effective way forward. Cost modelling also creates long-term relationships and builds trust between the buyer and supplier.

It helps in arriving at a cost estimate to guide negotiations and compare quotes provided by suppliers. Centralized should-cost modelling software enables supply chain teams to determine the true price of goods and services purchased.

What Is Benefit Of Cost Modeling?

Cost modeling helps businesses make informed decisions about pricing, production and other factors affecting costs by predicting the future costs of a product or service. It also allows investigating different scenarios and determining the most cost-effective way forward while building trust among both the buyer and the supplier.

Cost modeling software features centralized should-cost modeling tools enabling accurate pricing of goods and services purchased.

What Is The Purpose Of Cost Modelling?

Cost modelling is the process of predicting future costs of a product or service to facilitate informed business decisions on pricing, production, and cost factors. It helps to understand the costs incurred and the value derived from proposed investments. The advantages of cost modelling include better supplier relationship management, cost-effective decision making, and long-term business relationships.

Should cost modelling software offers digital manufacturing simulations and estimated cost analysis for cost negotiation and comparison.

What Are The Advantages Of Cost Model?

Cost modeling improves supplier relationship management, allowing for coordination and leveraging of their market insights. Long-term relationships can be built, trust can be established between both parties. Cost modeling also helps businesses make informed decisions about pricing, production, and other aspects affecting costs.

Conclusion

Cost modeling software is an effective tool that helps businesses make informed decisions about pricing, production, and other factors that affect costs. It also improves supplier relationship management by building trust among both the buyer and the supplier. Should cost modeling software, like GEP NEXXETM features and aPriori, provides detailed cost analysis based on digital manufacturing simulations.

Ultimately, utilizing should cost modeling software can empower you with the information you need to determine fair prices and make confident decisions.

Leave a Reply